Introduction to Soft Starters

Soft starters are crucial devices for the efficient and safe control of electric motors in various industries. When activating a motor, soft starters progressively regulate the power supply, minimizing mechanical stress and peak currents that can compromise both the integrity of the motor and the stability of the electrical network. This protective capability not only preserves equipment but also optimizes operational efficiency and generates significant energy savings.

How Do Soft Starters Work?

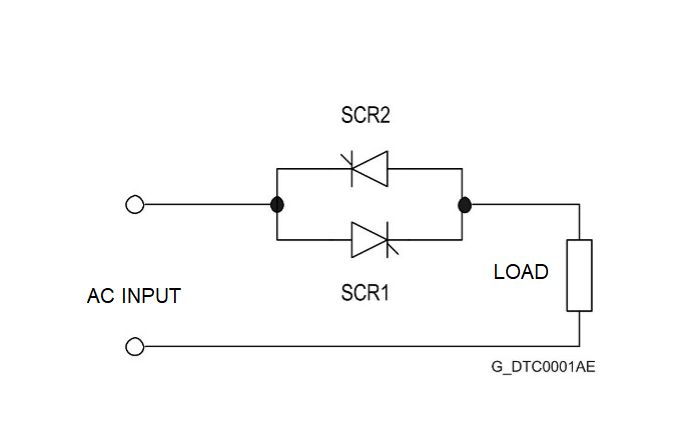

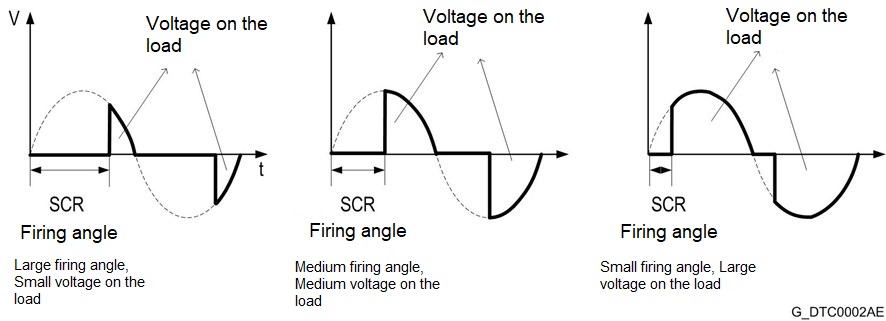

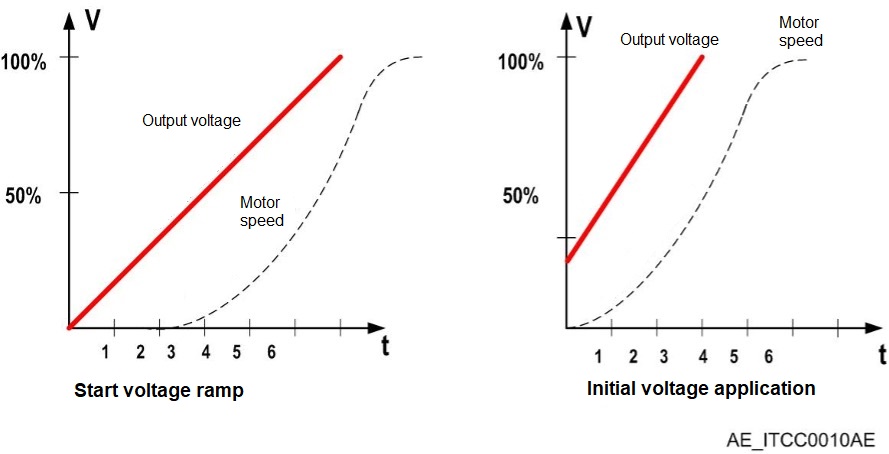

Soft starters adjust the voltage delivered to the motor using thyristors or silicon-controlled rectifiers (SCRs). These components facilitate a controlled increase in voltage until the level required for normal motor operation is reached. This meticulous voltage control avoids the current spikes typical of direct starts, effectively managing motor acceleration to minimize wear and extend its lifespan. Soft starters are particularly beneficial for motors that do not require full torque at start-up or that operate with heavy loads susceptible to damage during abrupt starts.

Power Electronics static starters have cutting power over all three phases, including a set of anti-parallel thyristors per phase.

Image: Anti-parallel Thyristor Connection

Image: RMS Voltage applied to the load

Image: Output voltage selection examples

Benefits of Soft Starters

Implementing soft starters brings multiple advantages:

• Motor Protection: They limit mechanical stress on the motor and other system components, reducing the risk of failures and breakdowns.

• Energy Savings: By avoiding the use of excessive energy during start-up, soft starters can result in considerable savings in operating costs.

• Increased Productivity: With fewer stoppages for maintenance and failures, processes become more continuous and efficient.

• Better Process Control: They allow smooth starts and stops, which is crucial for processes requiring precision and smooth material handling.

Common Industrial Applications

Soft starters are used in a variety of applications, including:

• Heavy Industries: Such as mining and metal manufacturing, where controlling heavy machinery like mills and presses is necessary.

• Water Treatment: In pumps and fans, ensuring a smooth start that protects infrastructure and optimizes energy consumption.

• Ventilation and HVAC Systems: To start fans and compressors, protecting systems against water hammer and other mechanical loads.

• Material Handling: In conveyor belts and lifting systems, where controlled starts are required to handle materials properly without causing damage.

Recent Technological Advances

Soft starter technology has evolved to include significant improvements in user interface and the integration of intelligent functionalities, enabling remote monitoring and control via IoT. These advances facilitate the adjustment of start-up parameters from advanced digital interfaces, enhance diagnostics, and anticipate maintenance, reducing downtime and increasing operational efficiency.

Guide to Selecting the Right Soft Starter

Selecting the right soft starter for a specific application requires careful consideration of several technical and operational factors. Here is a detailed guide to help you make the most informed decision:

• Nominal Voltage and Current: Start by verifying the nominal voltage and current the motor requires under normal operating conditions. These two parameters are essential to ensure the starter can handle the motor's electrical load without risk of overload.

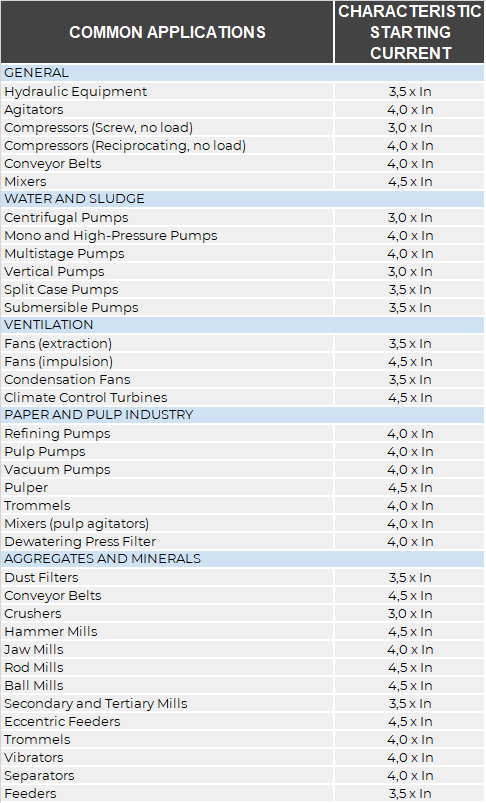

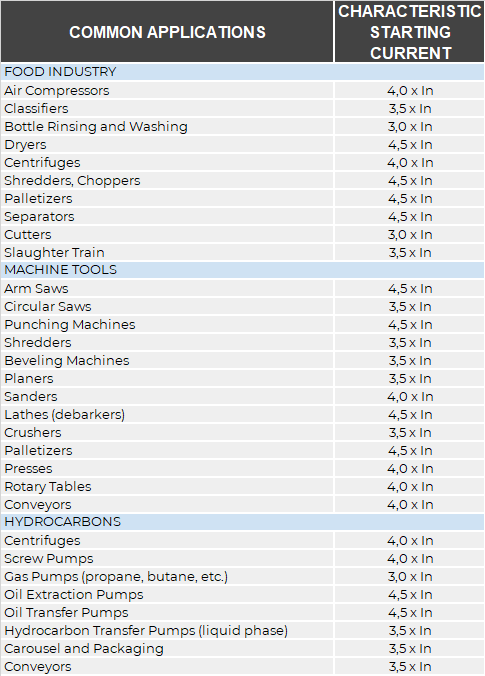

• Specific Application: Depending on the motor's application, it is crucial to understand how many times the rated current rises during start-up. This factor varies according to the type of load the motor is handling and is decisive in selecting a starter that can adequately manage these peaks without degrading either the motor or the starter itself.

• Number of Starts per Hour and Time Between Starts: Evaluate the frequency with which the motor will need to start within a standard time period. A high number of starts per hour may require a starter with more robust capabilities, especially in terms of heat dissipation and durability.

• Bypass Contactor: Consider starters that include a bypass contactor, such as the V6 series from Power Electronics. This component is crucial for reducing wear on the starter by switching the motor operation to a direct connection after the start-up period, improving efficiency and extending the lifespan of both the motor and the starter.

• Application Table: The following tables indicate the most common applications and the number of times the nominal current rises during start-up. This table is an invaluable tool for making an informed selection based on specific and comparable data.

Image: Characteristic Starting Current in Common Applications 1 of 2

Image: Characteristic Starting Current in Common Applications 2 of 2

How to Interpret the Selection Code of Your Soft Starter with Bypass

Understanding how to correctly interpret the selection code of a soft starter with bypass is crucial to ensure you choose the right equipment for your needs. This code provides detailed information about the starter's characteristics and capabilities, allowing you to make an informed decision about its suitability for a specific application.

Selection Code Breakdown:

Sometimes we can find codes in this format, let’s see how to interpret it:

AC53b 4.0-30:330

The typical code for a soft starter with bypass may seem complex at first, but each segment of the code has a specific meaning that helps identify the starter's characteristics. Here we explain what each part of the code means:

• Starting Current (Example: 4.0xIn): This value indicates how many times the nominal current (In) of the motor can rise during start-up. A value of 4.0xIn means that the starter can handle a starting current up to four times the motor's nominal current.

• Use Category Code (AC53b): This code refers to the usage category of the starter according to IEC standards. AC53b specifically indicates that the starter is designed for soft start and stop applications.

• Start Duration and Number of Starts per Hour (Example: 3.0-30:330):

• 3.0-30 represents the maximum overload duration allowed during start-up, in seconds.

• 330 indicates the maximum number of starts per hour that the starter can safely perform.

Tips for Selecting Your Next Soft Starter with Bypass:

1. Evaluate the Application: Determine the starting current and the frequency with which the motor needs to start. These factors are decisive in selecting a starter that can effectively handle the load without suffering damage.

2. Consult the Code: Use the selection code to verify that the starter meets the specific requirements of your application, paying attention to the current handling capacity and the usage category.

3. Current Models: The V6 series offers improved features and greater efficiency than its predecessors, the V2 and V5. Make sure to review the specifications of the V6 model to ensure it meets your needs.

4. Professional advice: If you have doubts about which model to select or how to interpret the selection code, do not hesitate to contact our sales department. Our team is available to help you choose the most suitable starter for your application, ensuring successful and efficient integration.